The advantages of cement block are numerous, and Fixolite block scores in every respect:

🆚

1. 🌱 Lower carbon footprint - RE2020

✔️ Yes. Wood cement (often wood chips bonded with cement) incorporates a proportion of bio-sourced material, which reduces its carbon footprint compared with EPS (derived from petrochemicals). This makes it more compatible with the requirements of the RE2020.

2. 🌬️ Breathable, natural material

✔️ Yes. Wood cement is breathable, which helps regulate interior humidity and reduces the risk of condensation/mould.

🫁 EPS, on the other hand, is completely impermeable to water vapour, and can cause problems if thermal bridges or waterproofing are poorly managed.

3. 🔥 Fire safety

✔️ Yes. Wood cement is classified as non-flammable (often M0), unlike polystyrene, which melts, spreads fire and gives off highly toxic gases (styrene, benzene, etc.).

⚠️ This is a major difference, especially indoors.

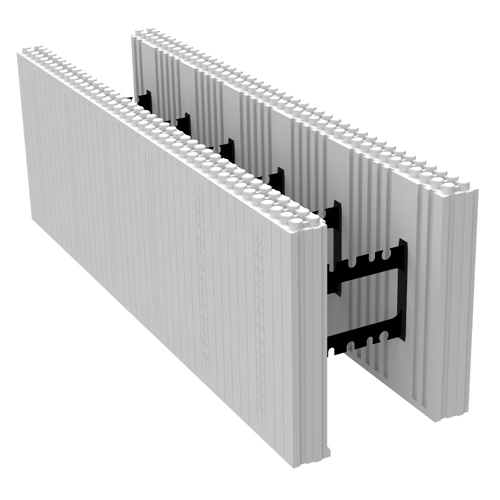

4. 🛠️ Easy to install (self-build)

✔️ Yes. Wood-cement blocks are often lightweight, easy to handle and can be sawn easily, which is appreciated in self-construction. No special tools are required, as is the case with some EPS insulating formworks.

5. 🌞 Thermal inertia (summer comfort)

✔️ Yes. Wood cement has good inertia (thermal mass), which helps to smooth out temperature variations.

❄️ Conversely, EPS on the inside blocks heat exchange with the mass of the wall, which is detrimental to summer comfort.

6. 🔇 Acoustic comfort

✔️ Yes. Wood cement is much better acoustically than EPS. It absorbs airborne and impact noise. EPS performs poorly in this respect, especially in lightweight walls.

7. 🔨 Mechanical strength and durability

Wood cement is a strong, durable material. It is resistant to impact, damp, rodents and mould.

EPS is fragile, easily perforated and subject to ageing if poorly protected.

8. ♻️ Recyclability/End-of-life impact

Wood cement is more easily recycled or reused, whereas EPS is very difficult to recycle in practice (large volume, few channels). In the event of deconstruction, EPS becomes a problematic waste product.

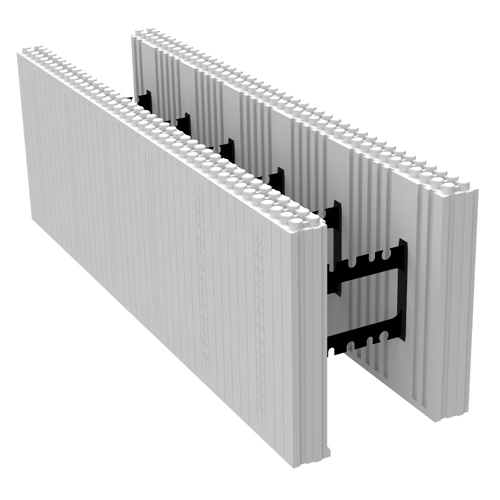

9. 🔧 Constructive versatility

Wood-cement blocks are often load-bearing, allowing simple construction without additional structures. EPS blocks (insulated concrete forms) require concrete to be poured and thermal bridges to be managed, and are sometimes ill-suited to certain seismic or damp areas.

10. 😌 Indoor air quality

Wood cement emits no VOCs or toxic gases, unlike polystyrene, which can release pentane (during manufacture) or styrene (in the event of fire or excessive heat).

🧱 To sum up:

|  | |

|---|---|---|

| Criteria | Wood-cement | PSE block |

| Carbon footprint | ✅ Low | ❌ Very high |

| Thermal inertia | ✅ Good | ❌ Very low |

| Summer comfort | ✅ Yes | ❌ Bad |

| Acoustic comfort | ✅ Good | ❌ Low |

| Breathable | ✅ Yes | ❌ No |

| Fire safety | ✅ Non-flammable | ❌ Toxic release |

| Self-build | ✅ Easy | ⚠️ Complex (formwork, concrete) |

| Recycling | ✅ Possible | ❌ Difficult |

| Health & IAQ | ✅ VOC-free | ❌ Risks (styrene) |

Sources and interesting articles:

1. Lower carbon footprint - RE2020 compatible

The wood-cement block contains wood chips, a bio-sourced material that stores carbon. It has a better carbon footprint than petrochemical materials such as EPS.

📎 Source : ADEME - Biobased materials and environmental performance

2. Breathable, natural material

Wood-cement blocks provide better moisture regulation and are breathable, making for a healthier home. EPS, on the other hand, is impermeable to water vapour.

📎 Source : CSTB - Hygiene, health and the environment in buildings

3. Non-flammable - increased fire safety

Wood cement is classified as non-flammable (M0). Polystyrene, on the other hand, is highly flammable and gives off highly toxic fumes in the event of a fire.

📎 Source : Fire safety - INRS

📎 Additional source (PSE sheet) : Expanded polystyrene safety data sheet - Knauf

4. Easy to install and suitable for self-builders

Wood-cement blocks are easy to handle, cut and lay. They do not require formwork or concreting like some EPS blocks.

📎 Source : Guide to building with wood cement blocks - Durisol

5. Better thermal inertia - Summer comfort

Thanks to their density, wood-cement blocks store heat during the day and release it at night, regulating the indoor temperature. EPS blocks these exchanges.

📎 Source : CEREMA - Summer comfort and thermal inertia

📎 Additional source : RE2020 - Ministry of Ecological Transition

6. Superior acoustic comfort

Wood-cement absorbs airborne and impact noise, unlike EPS, which lets sound through and causes discomfort in living areas.

📎 Source : Qualitel - Acoustic insulation in the home

7. Mechanical strength and durability

Wood cement is robust, resistant to moisture and pests, and has a long service life. EPS is sensitive to impact and UV light.

📎 Source : Technical sheet - Wood-cement block

8. Recycling and end-of-life impact

Wood-cement blocks can be recycled or reused. EPS is difficult to recycle and generates bulky waste.

📎 Source : ADEME fact sheet - ESDS of building materials

📎 Additional source - Polystyrene difficult to recycle : Zero Waste France